MHT – for perfect PET preforms

You are planning an exciting new bottle and need a preform mold?

You want to update your existing molds – e.g. for tethered caps?

High cavity molds, hotrunner and post mold cooling solutions, services, conversions and refurbishments: If you are looking for the perfect basis for your new bottle you should get in touch with MHT. We design and build high output PET preforms molds and offer customer-oriented services throughout the entire life cycle.

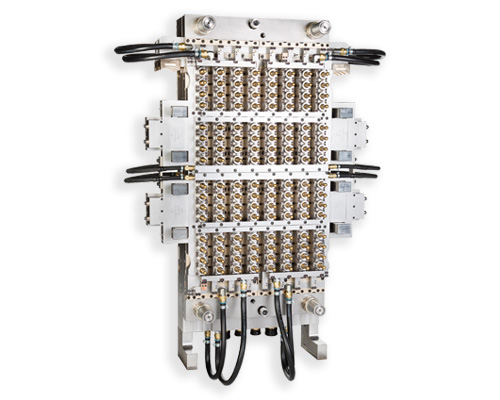

We are masters of flexibility. It does not matter which kind of PET system you are using: We know it and have already built molds for it. When it comes to high cavitation MHT is the leading company. We achieve fast cycle times and extremely constant shot weights by using our own hotrunner systems and our post mold cooling solution MHTcoolMAX.

If you require a new preform design (e.g. for short threads or tethered caps) we convert MHT molds as well as those by other suppliers. There are 2,500 MHT molds in the market worldwide and we support customers in more than 100 countries.